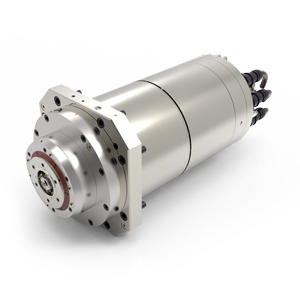

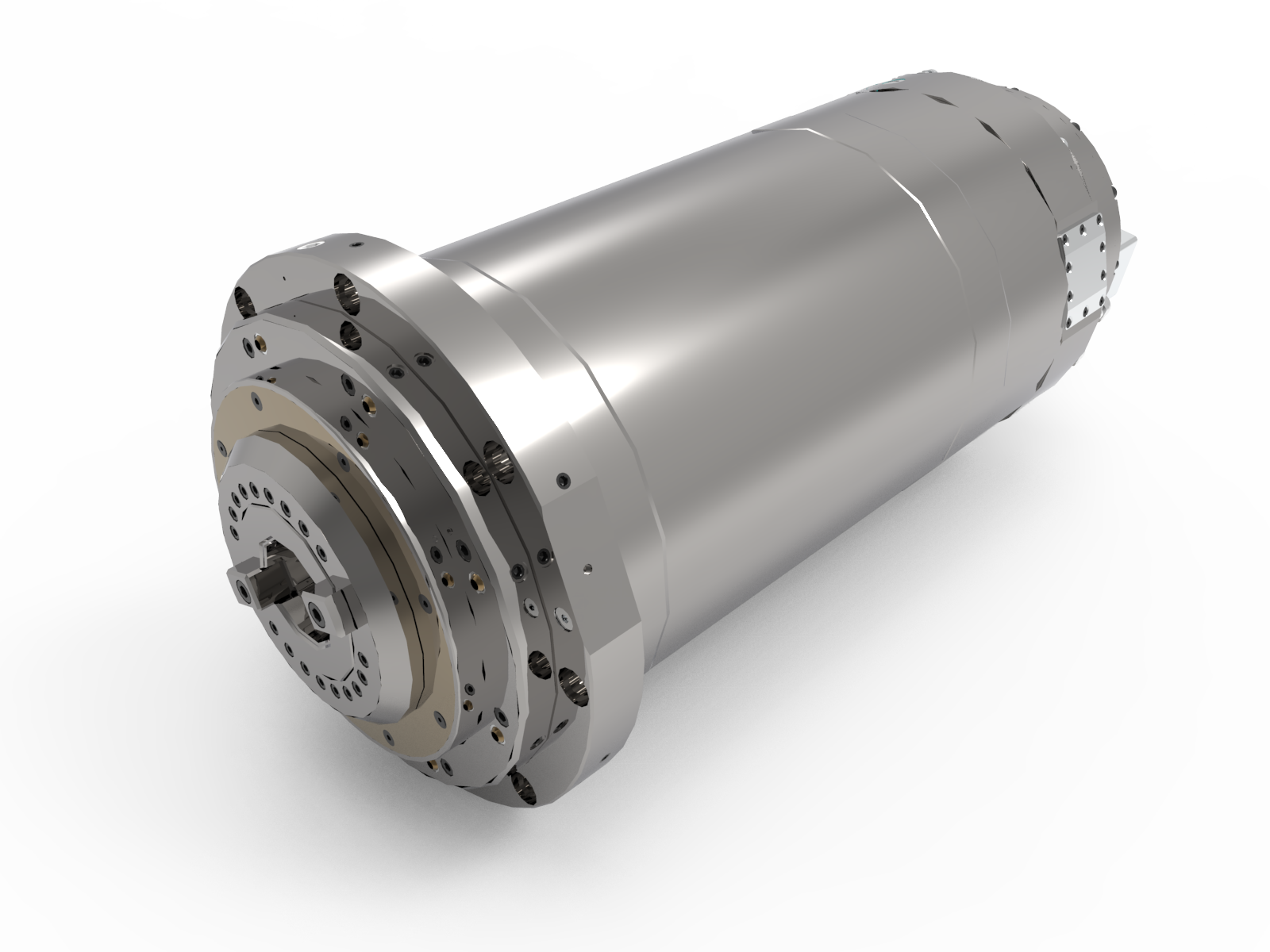

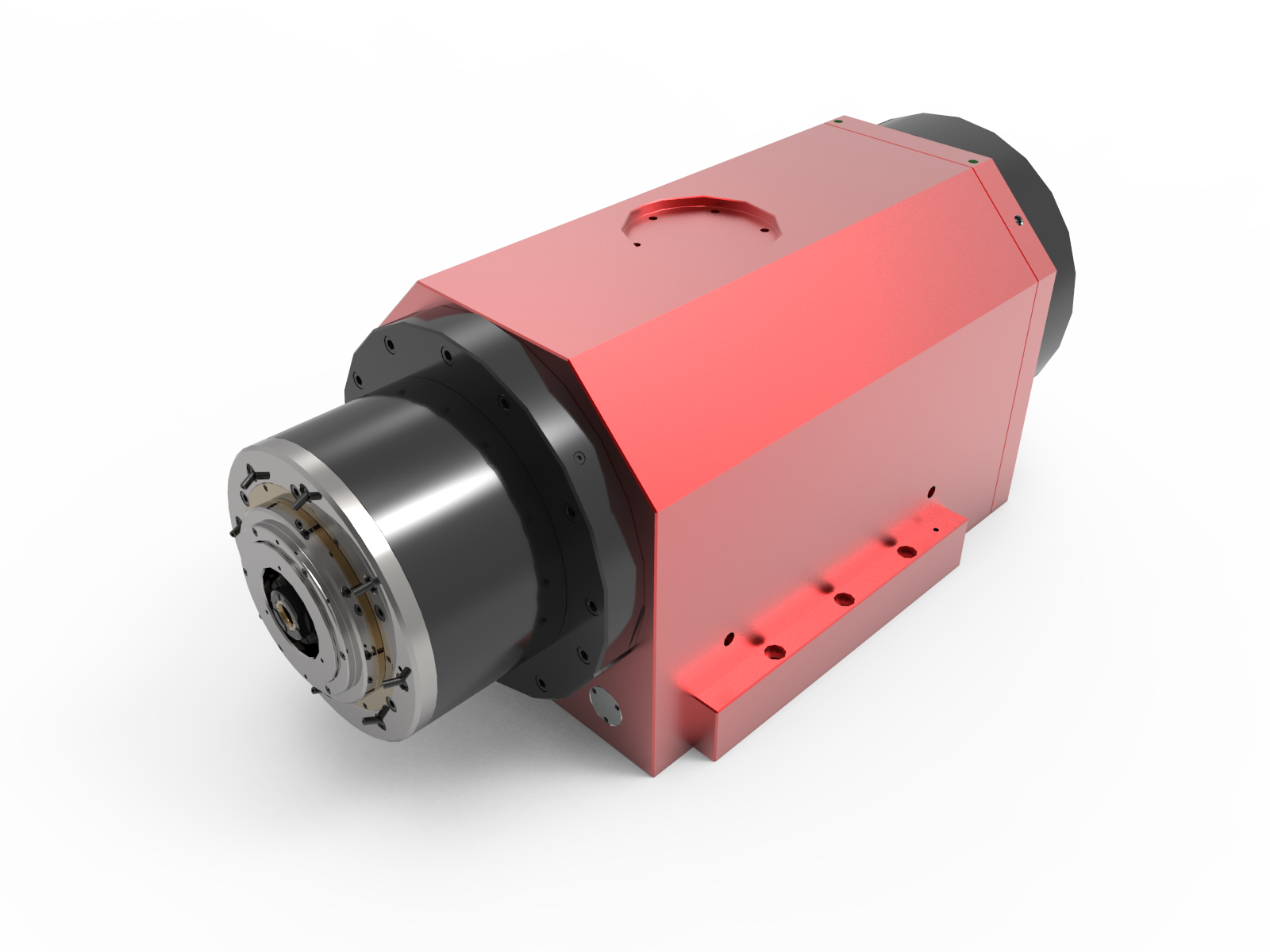

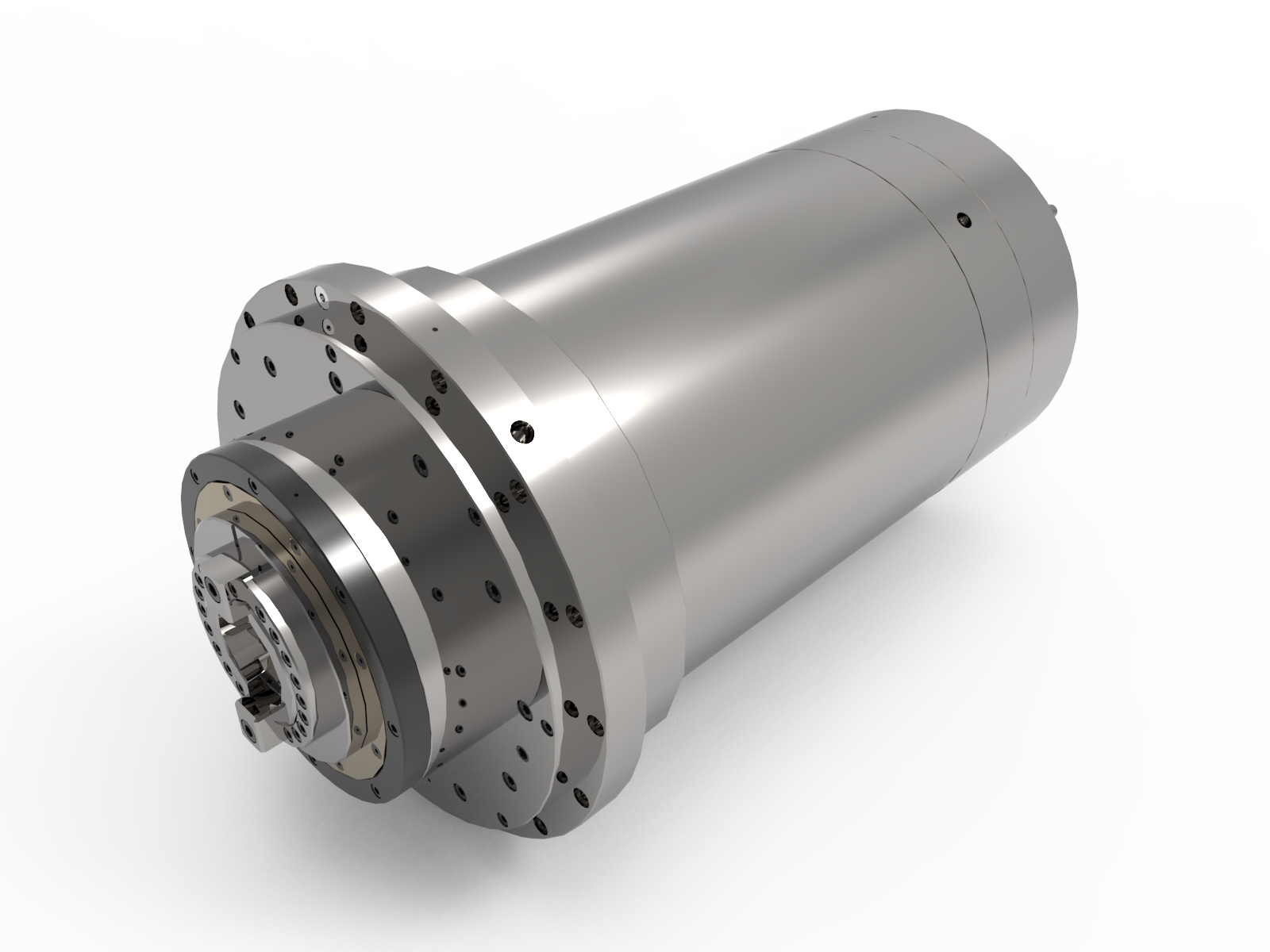

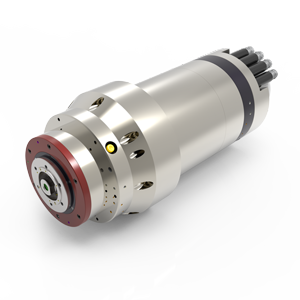

Milling ElectroSpindles

Electrospindles

The milling electrospindles made by Ima Tecno meet the multiple needs of mechanical processing on various types of materials.

We are able to design spindle lines according to the specific requests of the customer in terms of spindle axis stiffness, power and torque and other particular specifications.

No products with these combinations

Loading Results

Main Info for Milling ElectroSpindles

Thanks to the experience gained in the field, at Ima Tecno we are able to offer comprehensive advice on the design and manufacture of individual milling electrospindles, providing added value and superior quality to our mechanical components.

The milling electrospindles can be configured and customized according to the sector of use and specific characteristics such as:

- Power and torque

- Spindle axis stiffness

- High precision bearings of different types

- Type of bearing lubrication

- Tool change control system

- Cooling system

- Axis Positioning Control

- Fluid passage mode on axis

- Thermal probes

- Axis elongation control sensors

- Vibration detection sensor (accelerometer)

- Collision warning and monitoring sensor

Contact us or fill out the form for further information or specific requests.

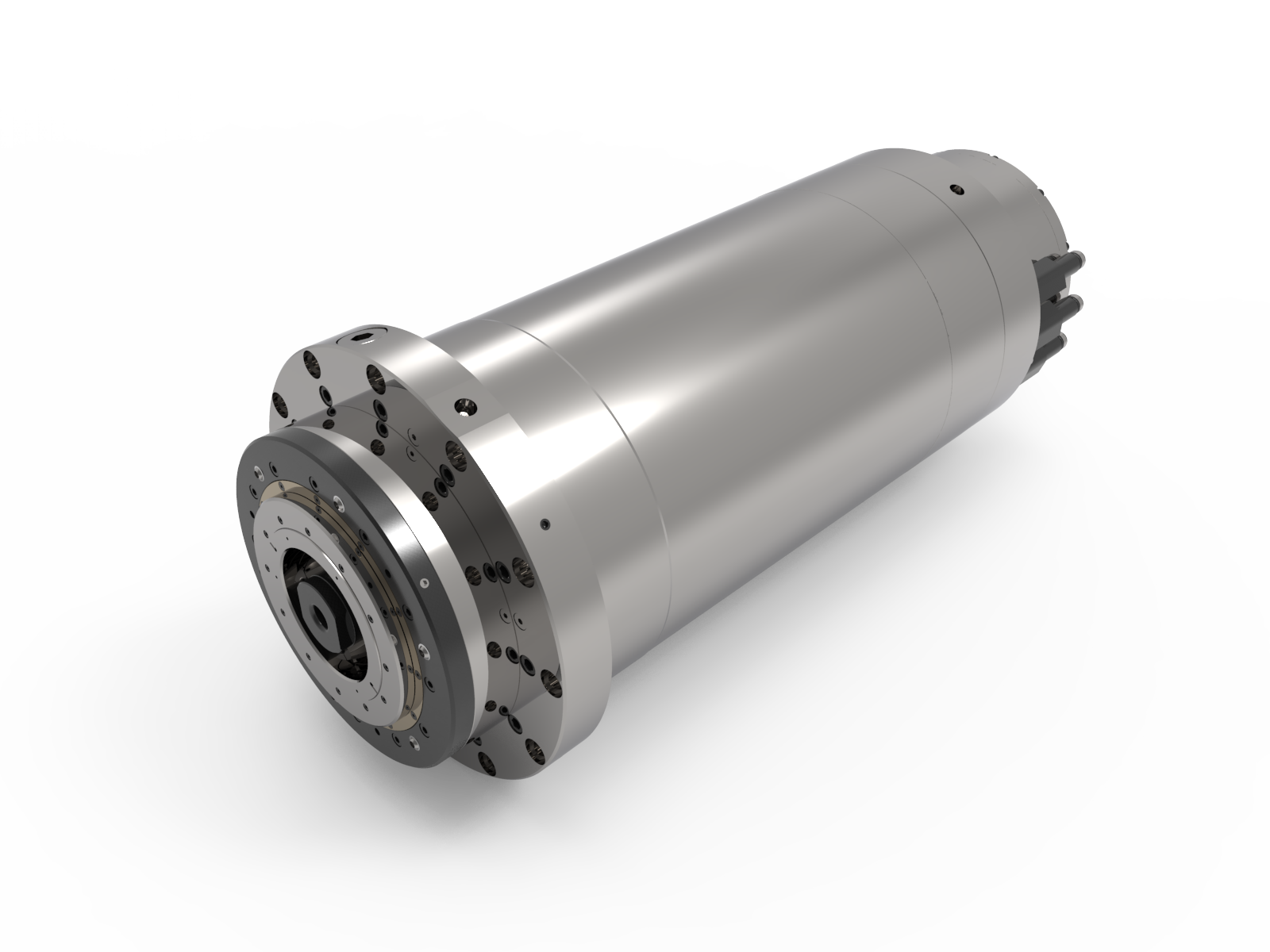

Types of Milling ElectroSpindles

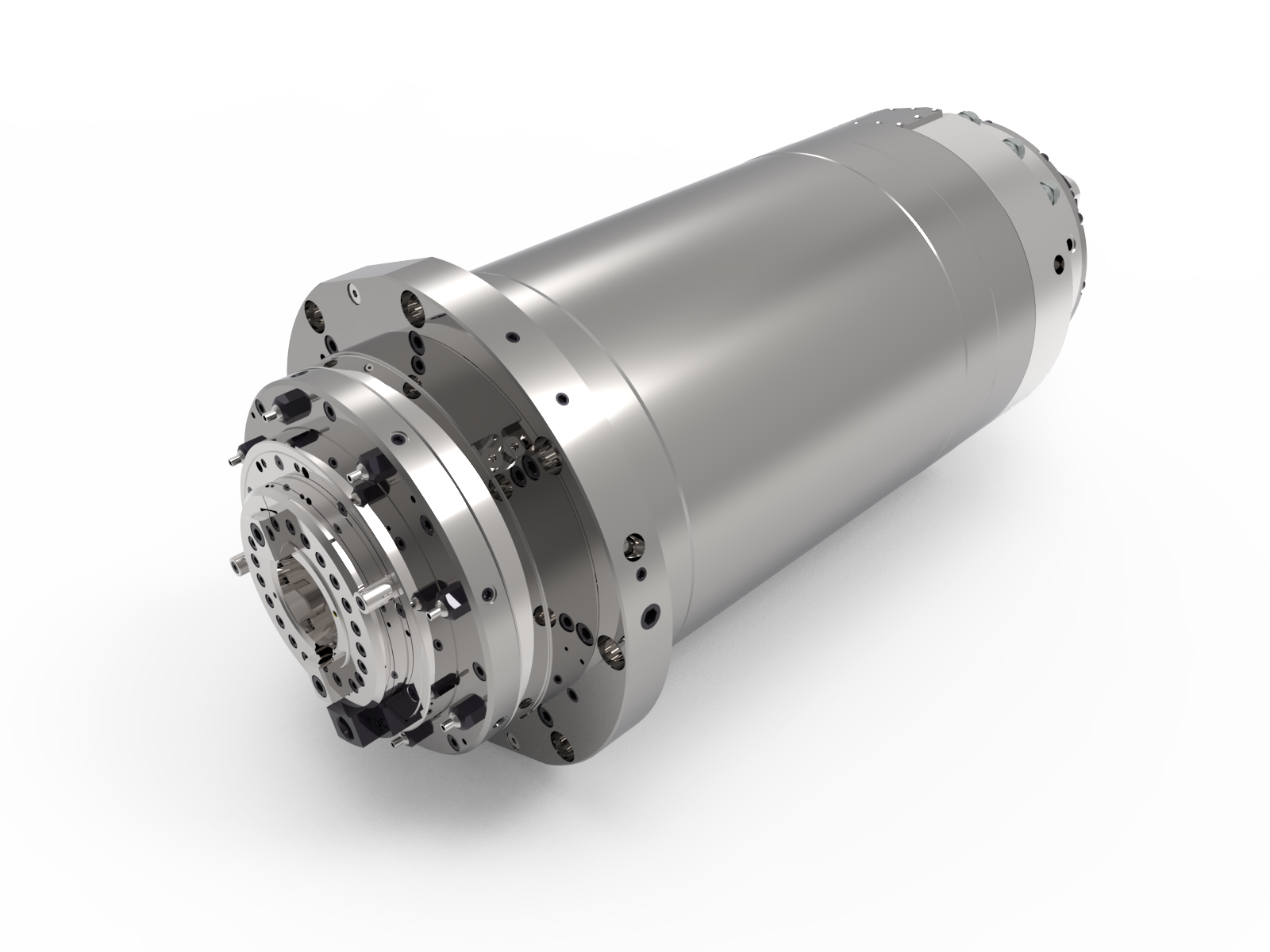

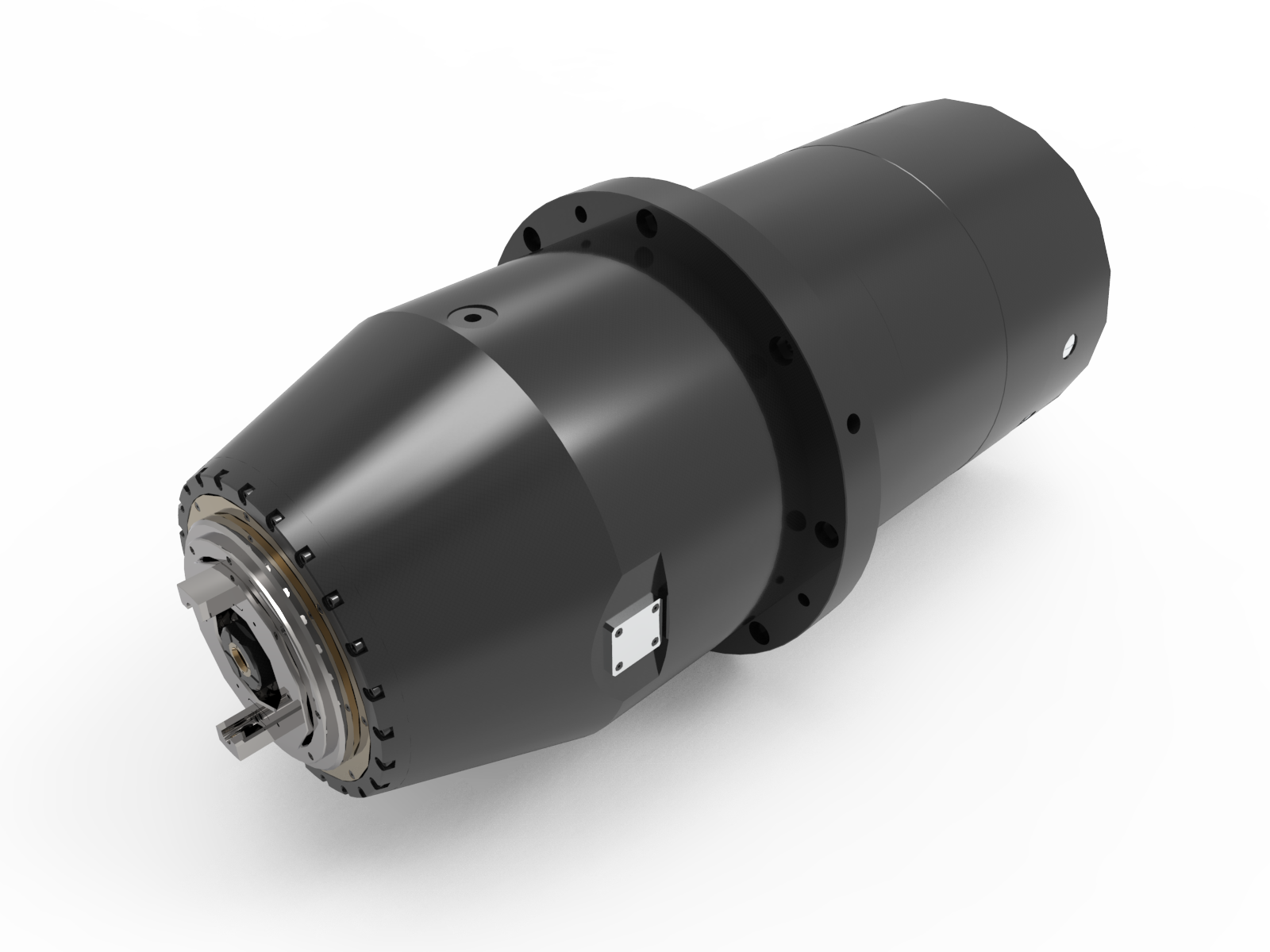

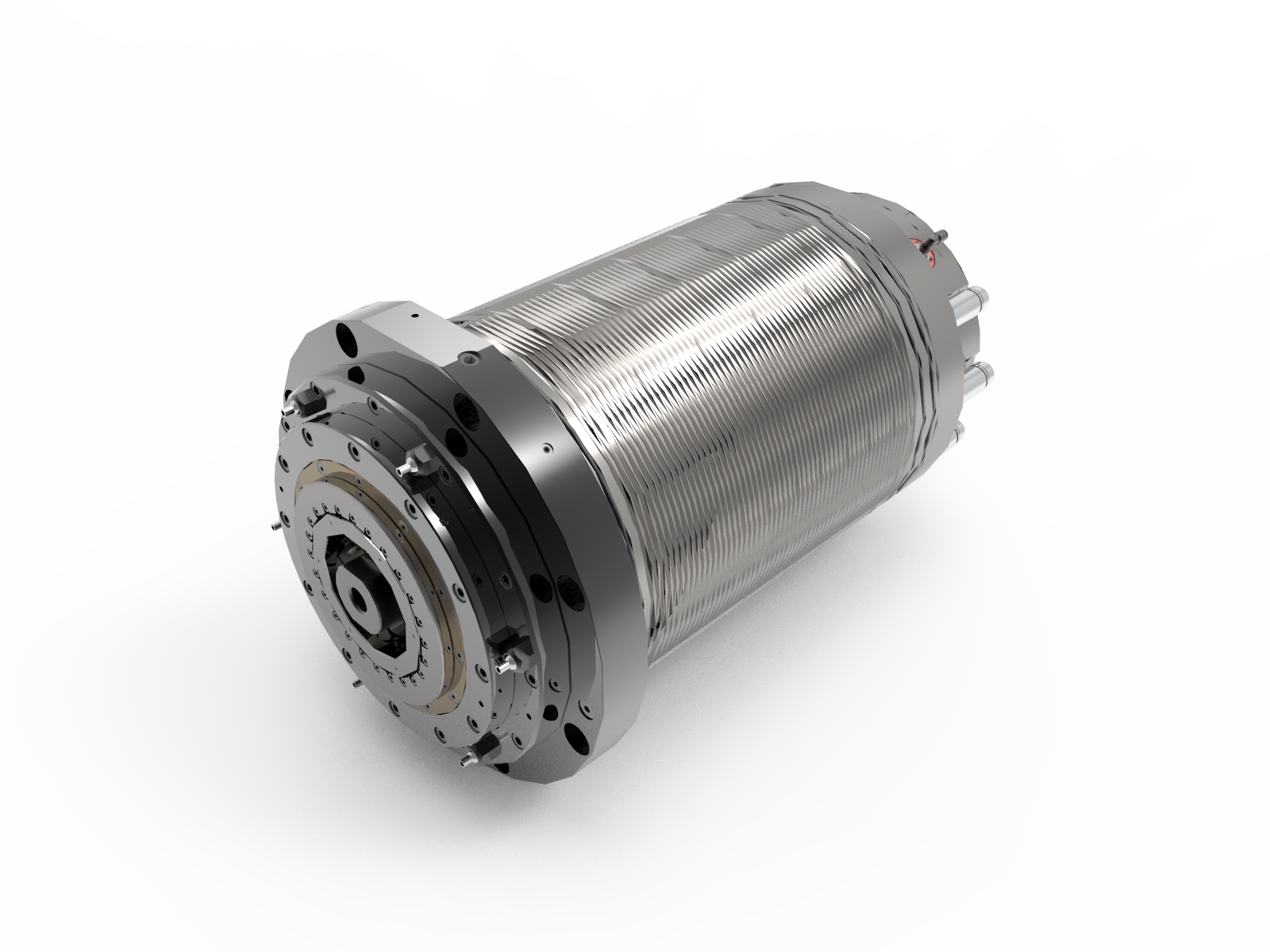

The Ima Tecno milling electrospindles in the aeronautical field are recognized and appreciated by the major world manufacturers.

Today Ima Tecno continues to develop milling electrospindles in the aeronautical field by implementing the most recent technologies available.

The essential characteristics for the Aerospace line milling electrospindles are:

- High power at high speeds for machining aluminum, carbon and resin components.

- High torque at low speed for machining titanium and alloy steel components.

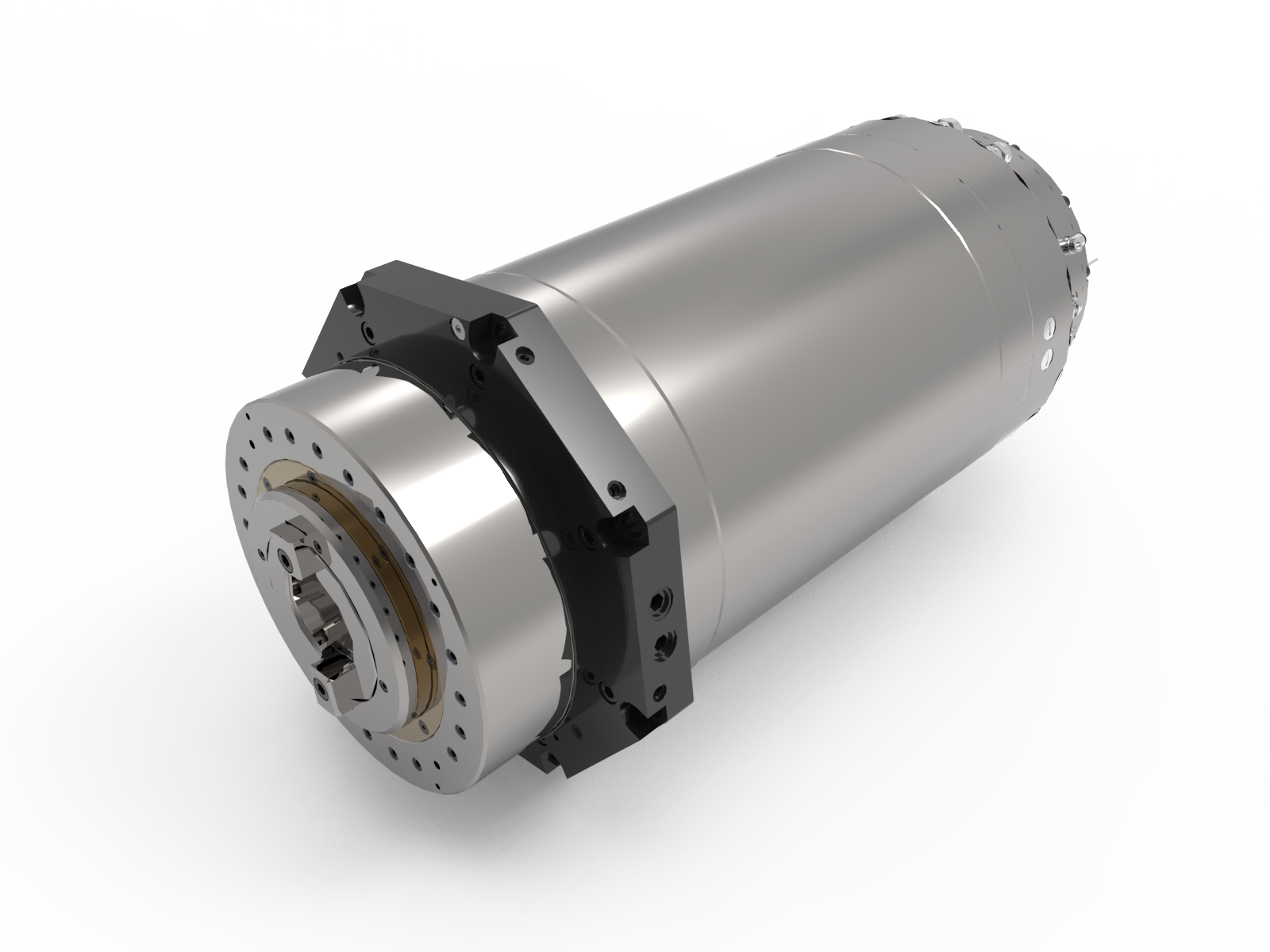

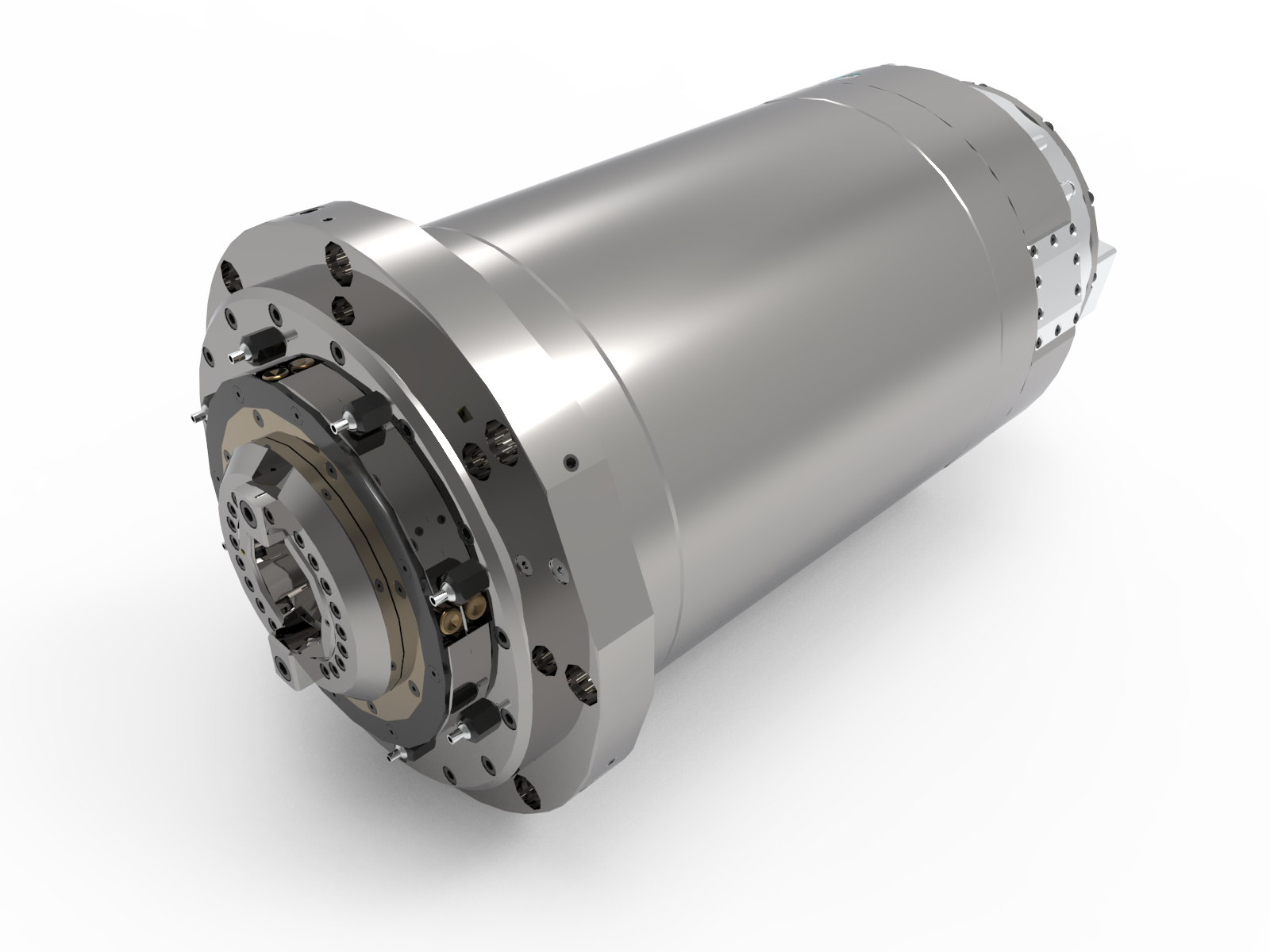

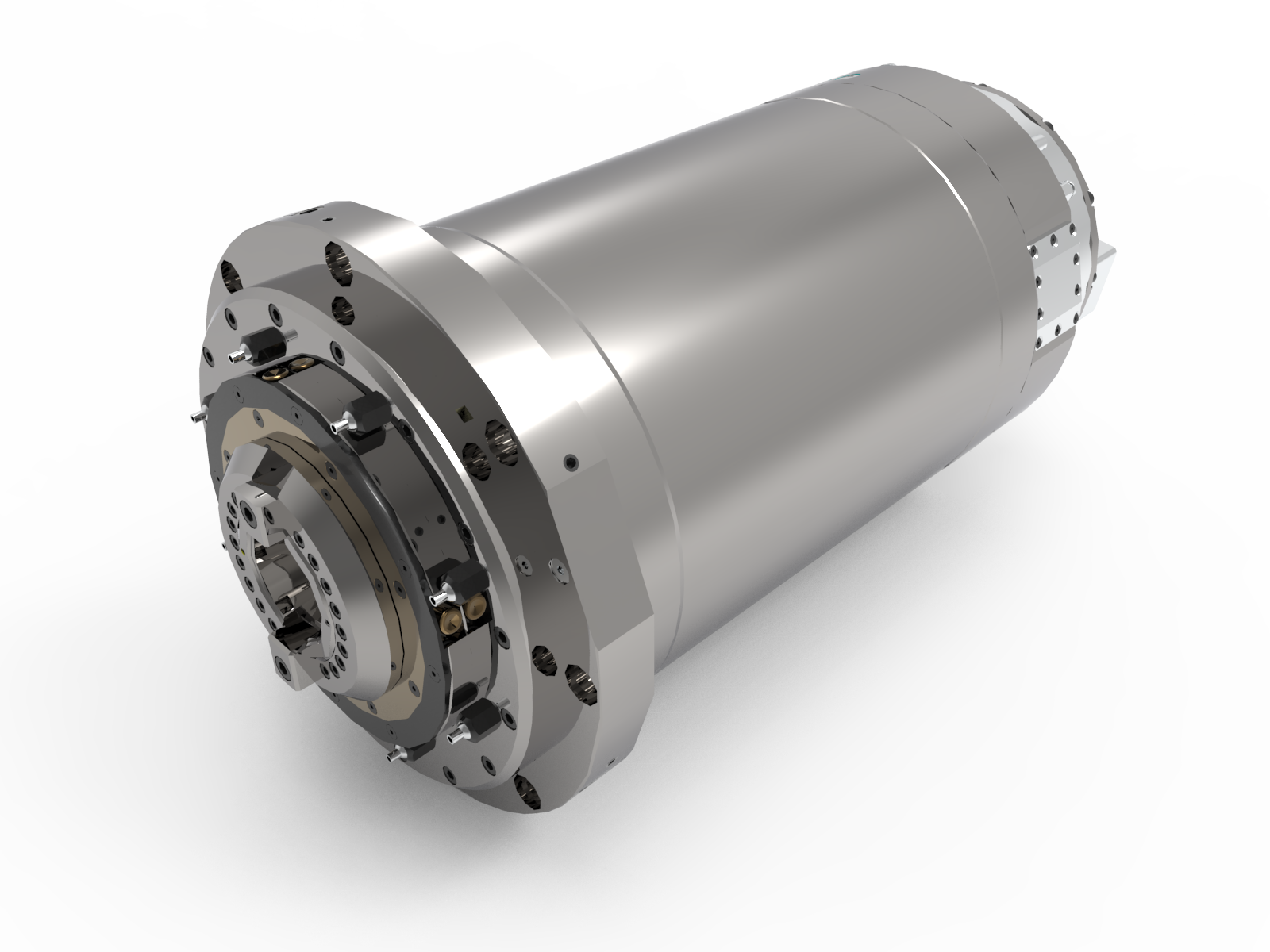

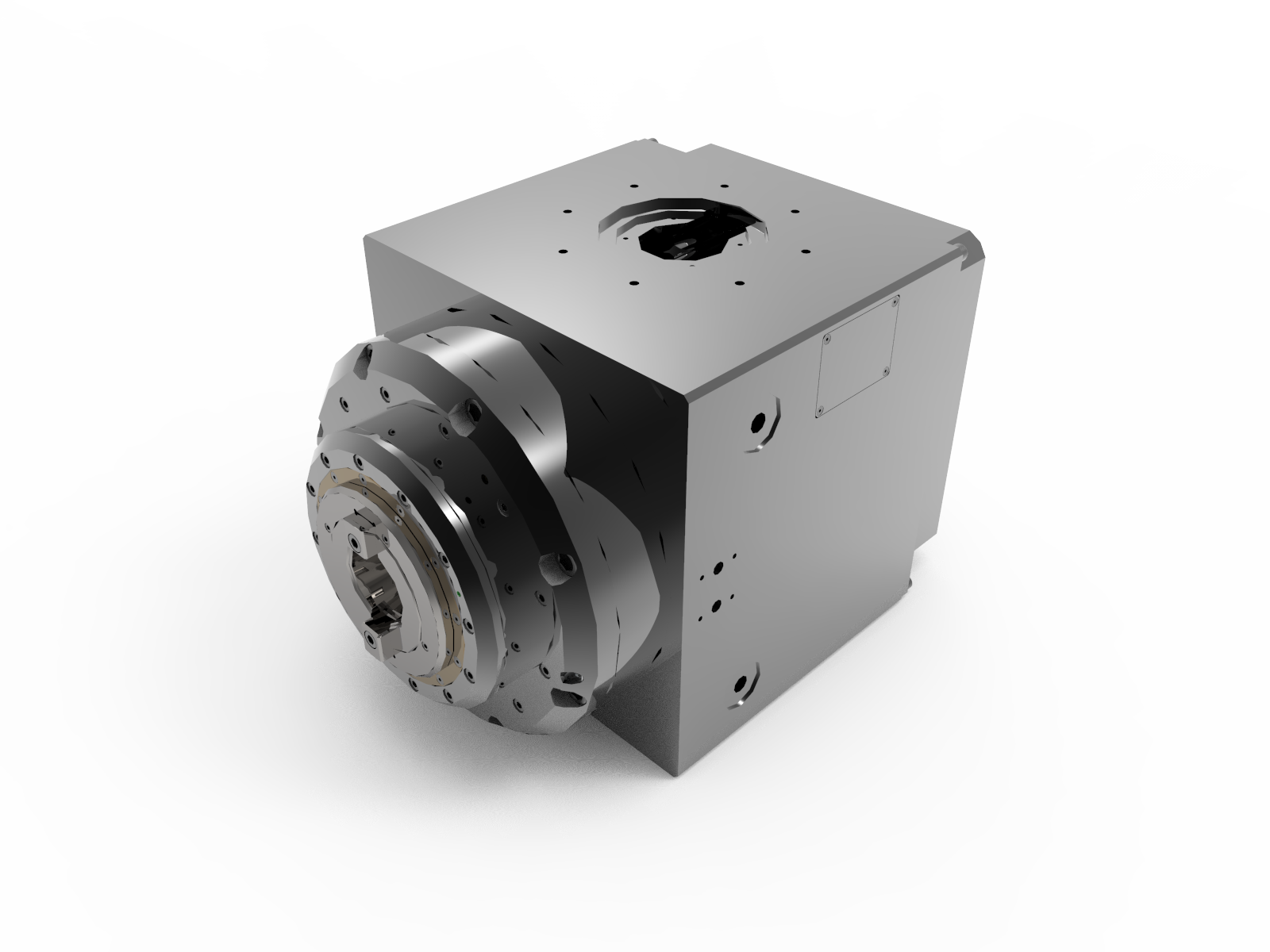

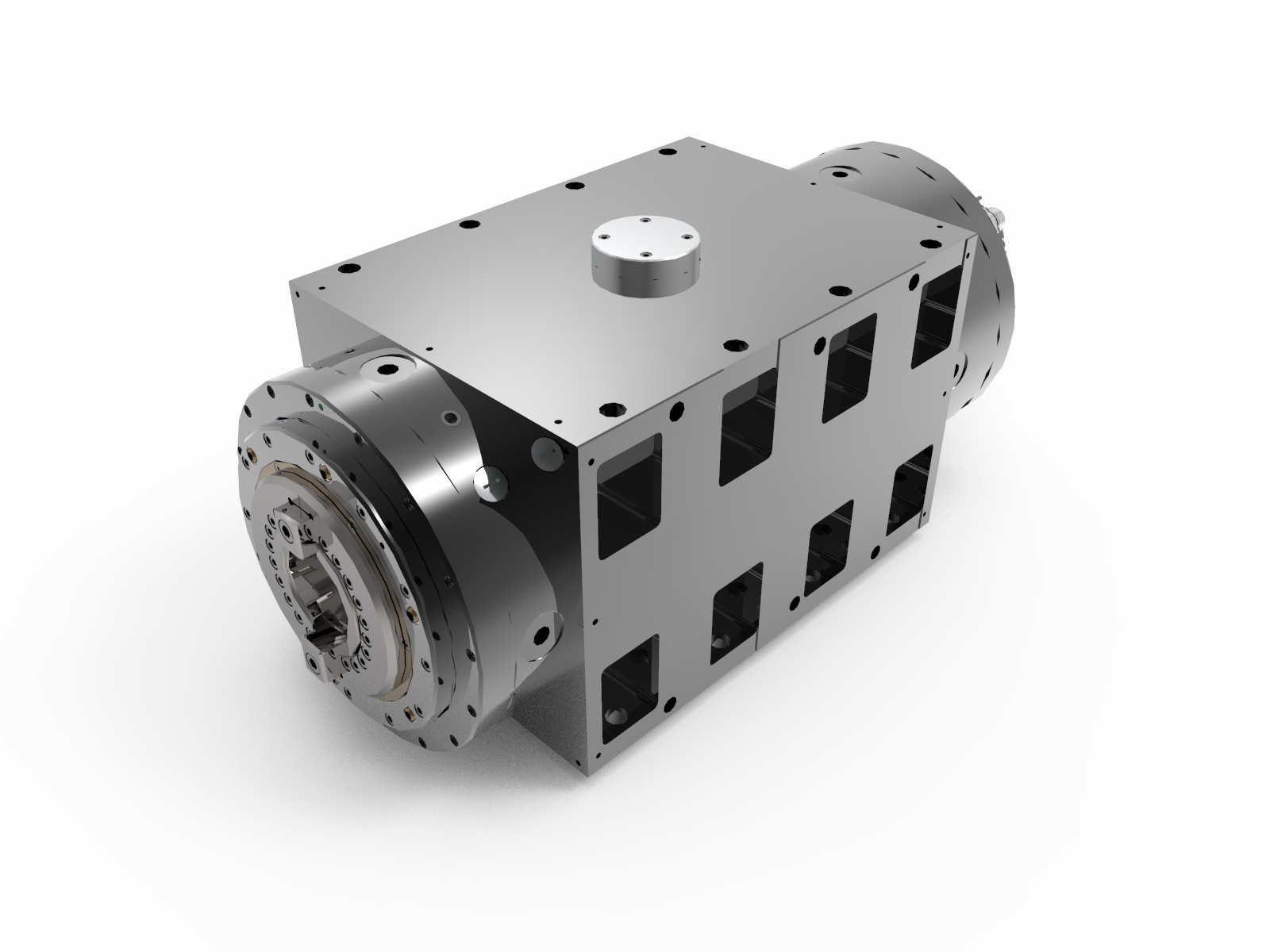

The "DW Line" milling electrospindles are built with high quality components and tested in the field in large quantities to meet the most complex needs of:

- automotive components processing where continuous work is required 360 days / year

- execution of many tool changes, 3,000,000 cycles per year

- rapid execution of the preventive assistance service

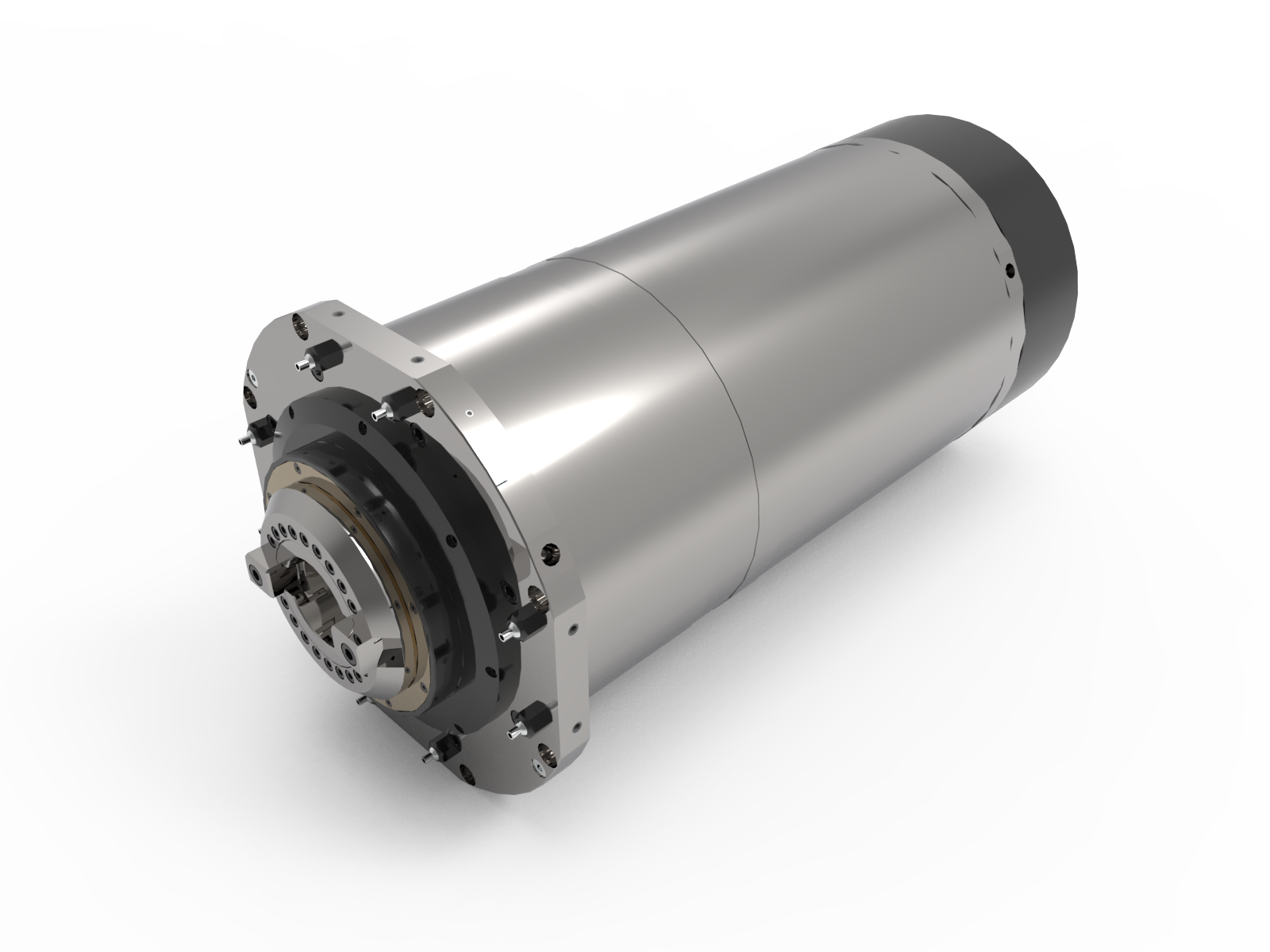

The "E Line" milling electrospindles are designed for machining centers where, due to the obvious quality of the work to be performed, it is necessary to guarantee the cost-effectiveness and reliability of the product.

The design solutions adopted guarantee the aforementioned characteristics.

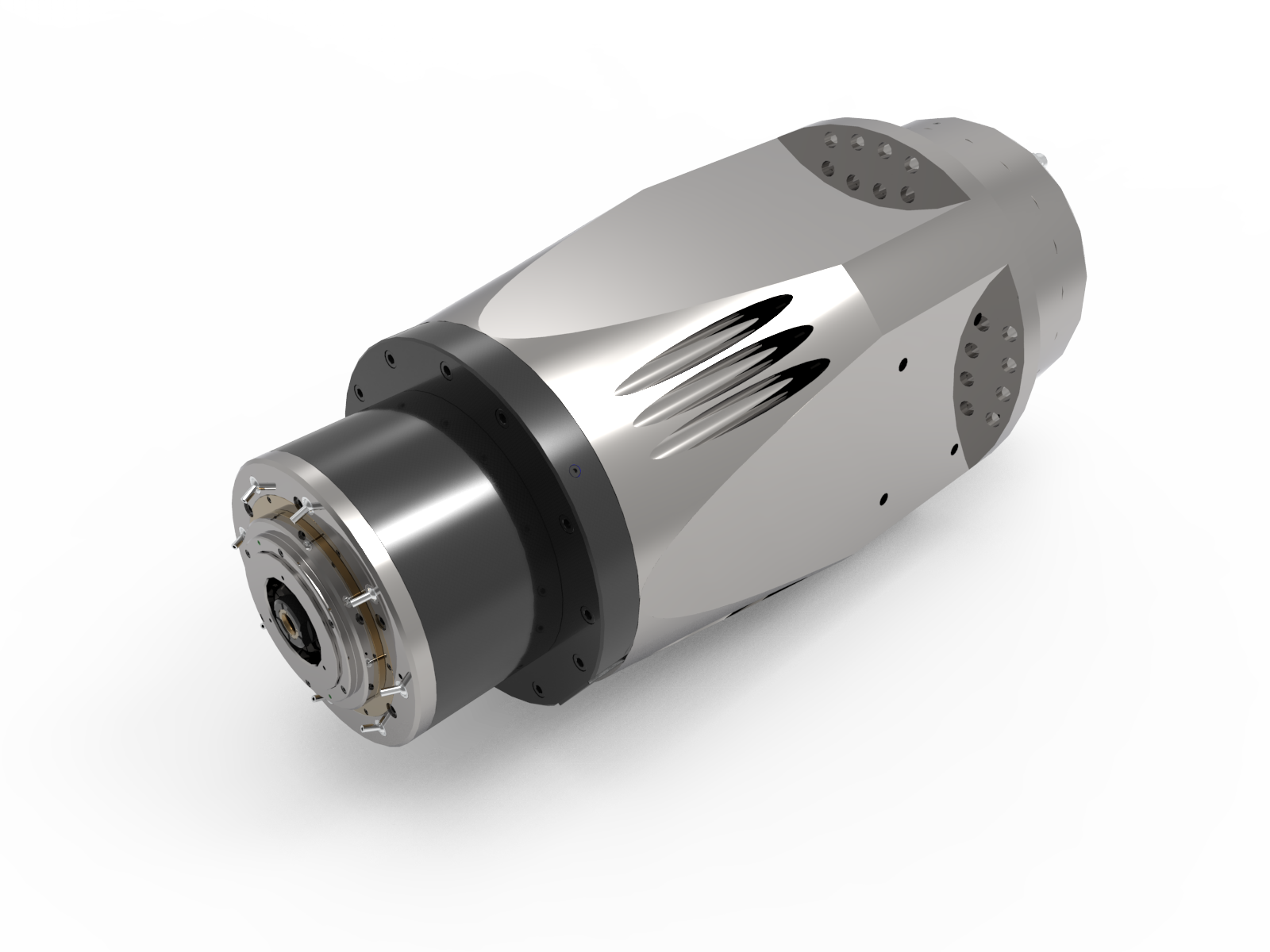

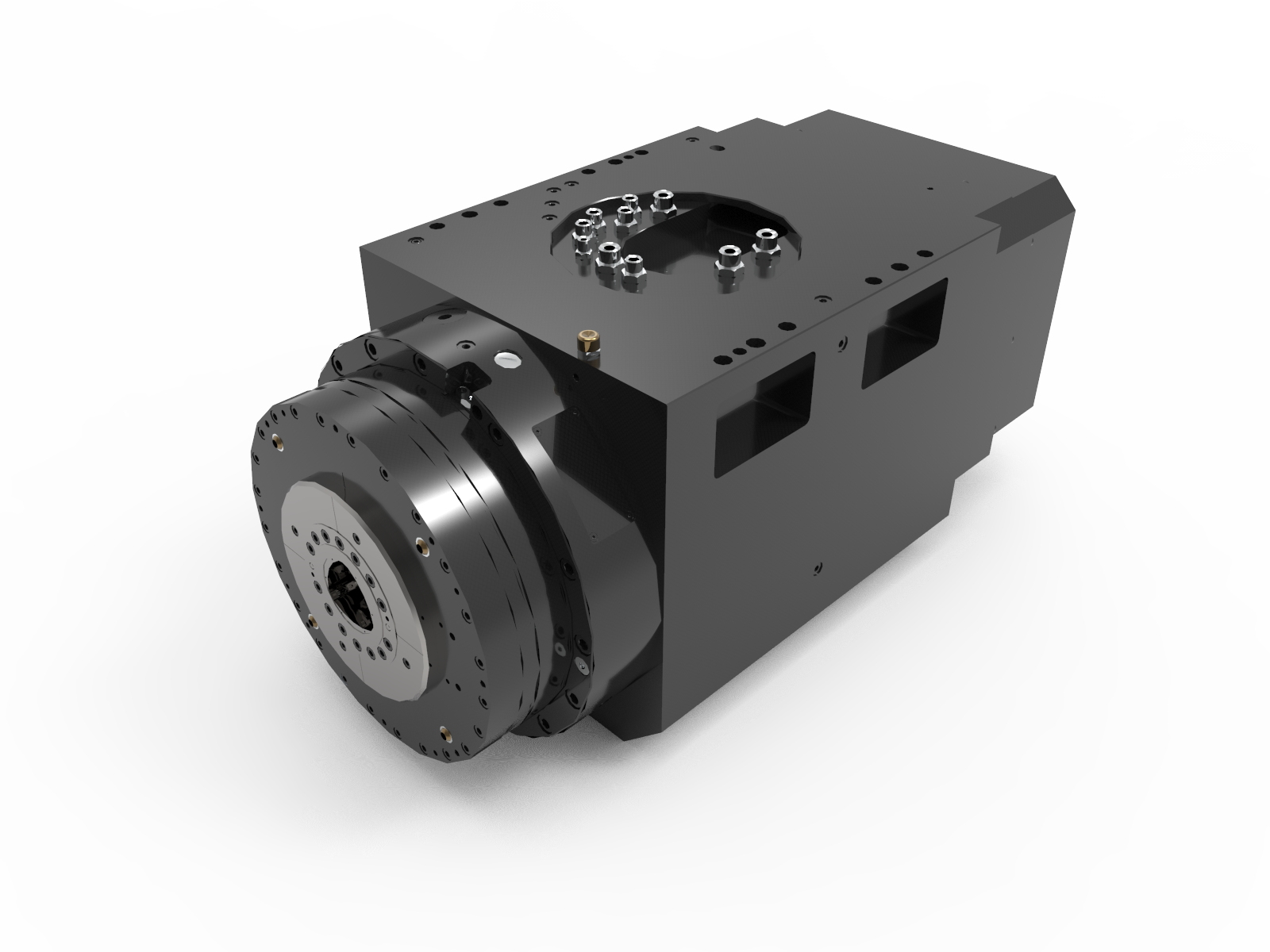

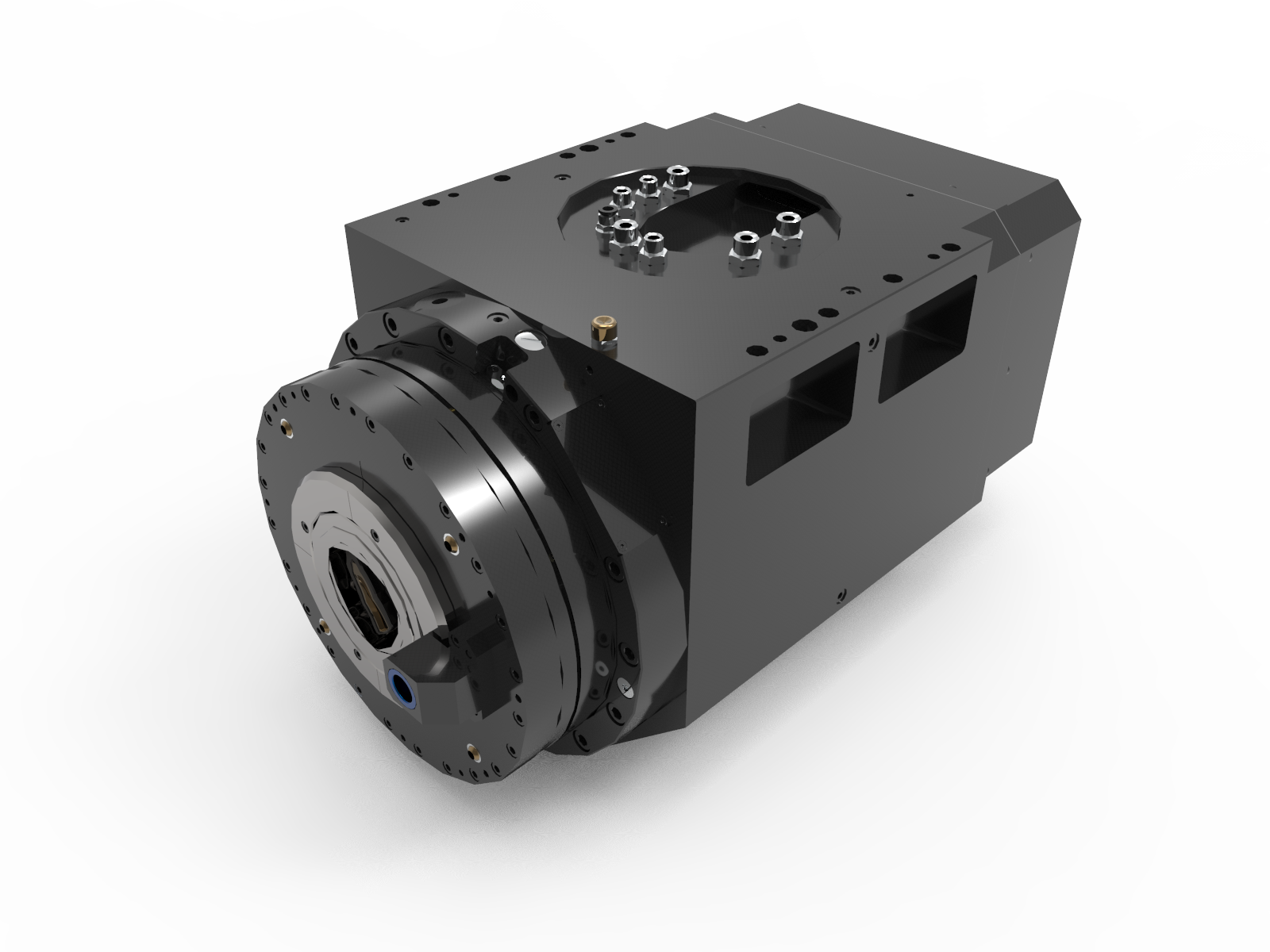

The "Horizon Line" milling electrospindles are specially designed for automotive applications where performance and reliability must be maximized.

These electrospindles are characterized by very high dynamics in terms of rotation and tool change.

Ima Tecno has developed over time different types of electrospindles particularly suitable for the various applications on machine tools dedicated to machining components in the following sectors:

- General mechanics

- Molds and dies

- Power